The manufacturing world is changing in big ways, all thanks to new tech. This isn’t just a passing phase. Rather, it’s a major shift in how we make everything, from the smallest gadgets to the biggest machines.

We will dive into how this tech boom makes manufacturing better and smarter. Major players aren’t the only ones experiencing this shift; it’s widespread and bringing in a new era of manufacturing marked by more intelligence, sustainability, and flexibility.

It represents a revolutionary phase that spreads its impact throughout the business environment. This transformation is driven by a range of technologies, from advanced robotics to sophisticated data analytics, reshaping the way we think about production and efficiency.

In this post, we will help you understand how technology is reshaping the manufacturing landscape.

Let’s dig in!

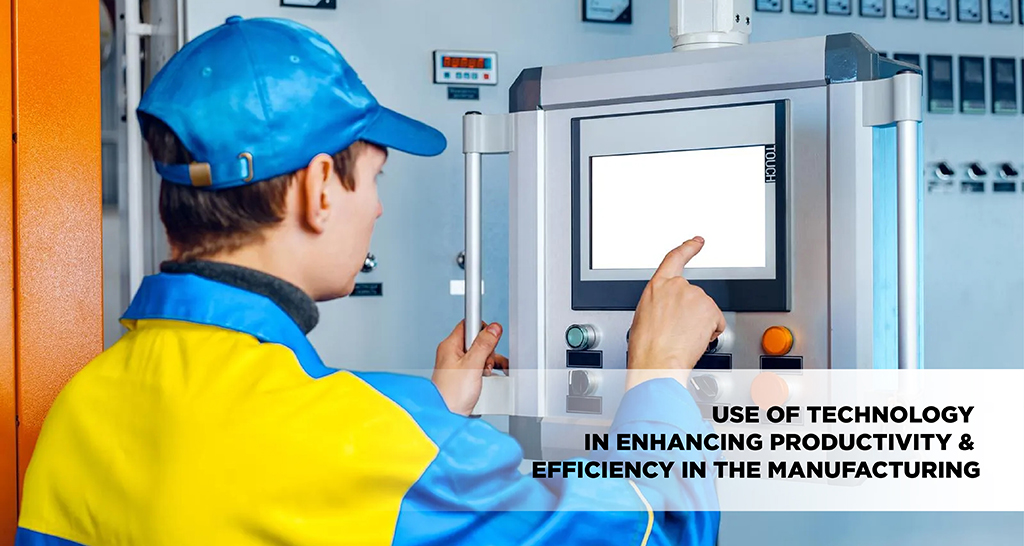

Utilizing Digital Revolution in Manufacturing

The role of automation and robotics in manufacturing is unmatched. Imagine a world where machines and robots work alongside humans, not just to replace manual labor but to enhance it.

Automation in manufacturing has led to significant improvements in productivity. Robots don’t tire, don’t need breaks, and can perform repetitive tasks with a precision that’s hard for humans to match. This means you can expect higher output, consistent quality, and reduced production times.

Power of IoT and Smart Manufacturing

The Internet of Things (IoT) has transformed manufacturing floors into smart environments. Sensors and connected devices collect and analyze data in real-time, allowing you to monitor and optimize every aspect of the production process.

This means you can anticipate maintenance needs, reduce downtime, and even predict and prevent potential system failures.

Leveraging Big Data and Analytics

In the world of manufacturing, knowledge is power. Big data and analytics provide insights that were previously unimaginable. By analyzing vast amounts of data, you can identify trends, improve quality control, and make informed decisions that boost efficiency and reduce costs.

Impact of Advanced Metrology For Precision and Quality Control

Precision in manufacturing is not just about adhering to specifications; it’s about ensuring efficiency, reliability, and innovation in production. Advanced metrology, championed by companies like Great Lakes Metrology, plays a critical role in this. By utilizing cutting-edge measuring tools and technologies, they help in achieving unparalleled accuracy.

This precision is vital in industries where even the slightest deviation can have significant consequences, such as in aerospace or medical device manufacturing.

Using such advanced metrology tools leads to improved product performance and compliance with international standards by setting new benchmarks in quality and precision.

Enhancing Quality with 3D Printing

3D printing, or additive manufacturing, has revolutionized prototyping and production. It allows the creation of complex, lightweight, and strong structures with a level of precision that traditional methods can’t match. This not only speeds up the design process but also opens up new possibilities in manufacturing custom and intricate parts.

Streamlining Supply Chain and Logistics

Efficient management of supply chains is crucial for timely production and delivery. Enterprise Resource Planning (ERP) systems integrate all parts of an operation, including procurement, production, sales, and distribution. This integration ensures that every part of your supply chain is in sync, reducing delays and improving customer satisfaction.

Advancements in Material Handling and Logistics

Technology has also revolutionized material handling and logistics in manufacturing. Automated guided vehicles (AGVs), drones, and advanced conveyor belt systems ensure that materials and products move through the factory floor and beyond with greater speed and accuracy, reducing manual labor and the potential for errors.

Ensuring Sustainability and Safety

As you adopt technology, it’s also essential to consider the environmental impact of manufacturing. Technologies like energy-efficient machinery, waste reduction systems, and sustainable materials benefit the planet. In fact, they also resonate with environmentally conscious consumers and can lead to cost savings in the long run.

Improving Workplace Safety

The integration of technology in manufacturing also plays a crucial role in enhancing workplace safety. Automated systems reduce the need for human workers to perform dangerous tasks, while wearables and sensors can monitor environmental conditions and alert workers to potential hazards.

Preparing for the Future Using AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are set to take manufacturing to new heights. From predictive maintenance to AI-driven quality control and even smart robotics that learn and adapt, the possibilities are endless. These technologies help you optimize current processes and guide you for a future where flexibility and adaptability are key.

Continuous Learning and Adaptation

The world of manufacturing technology is ever-evolving. To stay ahead, continuous learning and adaptation are crucial. This means not only investing in new technologies but also in the skills and training of your workforce. After all, the most advanced technology is only as good as the people operating it.

Sum Up

The integration of technology in manufacturing is no longer a luxury; it’s a necessity for survival and success in today’s competitive market. From automation and IoT to advanced metrology and AI, these technological advancements are not just about keeping up with the times; they’re about setting new standards in productivity and efficiency. The future of manufacturing is here, and it’s time to embrace it.